When you buy a new table saw, the adjustments you make will affect the quality of the saw's cuts for the rest of its life. Can you imagine how much extra effort may be required if the blade is not parallel to the miter gauge slots, or if the fence is not parallel to the blade? Even the best saw blades won't cut smoothly if the saw is not tuned up properly, and the best saws are never tuned as well as a craftsman would like when they leave the factory.

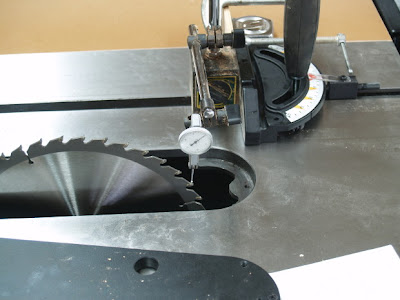

The photos above show the process. Use a dial gauge to check the front side of the blade, and the back side of the blade. Use the miter gauge and stop block clamped in place to index the gauge so that it is in the same position relative to the miter gauge slot at both the front and back of the blade. If it is not the same, loosen the bolts that secure the table top to the saw. Your manual that came with the saw will show their locations. The Grizzly has three. Adjust the top until the reading is the same at both the front and back of the blade. Almost as accurate is to use combination square as shown the third photo. Set the blade of the square so that when the body of the square rests in the miter gauge slot so that it just touches a tooth at the front side of the blade. Then check the back. If the blade doesn't touch just the same, front and back, adjust the position of the table saw top so it does.

Next adjust the fence. It should be perfectly parallel to the miter gauge slots and you can check by aligning it with the slot and using your sense of touch. The fence will have adjustment screws to allow you to fine tune it to provide a perfect cut.Check your manual for instructions.

Now, as soon as I have my saw connected to my dust collector system, I'll be ready for years of accurate cuts.

Hey, I love your photos..they are really nice...

ReplyDeleteNice tutorial. Reminds me to tune mine up.

ReplyDelete